Able to be automatic or gravity-fed, chain oilers significantly reduce the effect of wear and tear on the chain and sprocket as well as protecting against losses in power transmission and bad fuel. Read More…

Graco's lubrication equipment division manufactures products used to dispense, meter and transfer motor and gear oils, grease, hydraulic and transmission fluids, antifreeze and other specialty lubricants. Our team of designers and engineers are committed to providing quality technical service and support on all our products. Call us or visit our website today!

At LSP Industries, Inc., we specialize in delivering comprehensive lubrication system solutions tailored to meet the demanding needs of modern industries. We pride ourselves on our ability to design, manufacture, and support innovative lubrication systems that optimize machinery performance and ensure operational efficiency. Our team combines decades of expertise with state-of-the-art technology...

The expert team at American Design & Manufacturing has over 100 years of combined knowledge in the design of customized lubrication systems, hydraulic equipment, heat transfer systems, gearbox assembly, cleaning equipment, specialty fabrication and test equipment. We utilize state of the art equipment and CAD design systems to create the best lubrication and other equipment for your application.

At Oil-Rite Corporation, we specialize in designing and manufacturing high-quality lubrication systems that enhance the efficiency and longevity of industrial machinery. Our expertise lies in providing innovative solutions that ensure precise and reliable lubrication, reducing wear, minimizing maintenance costs, and optimizing performance across a wide range of industries.

More Chain Oiler Manufacturers

Chain oilers are most often utilized in power transmission applications in the marine, aviation and automotive industries. Motorcycles, cars, ships, airplanes and trucks are just a few examples of products that benefit from chain oiler use. Additional industries that benefit from the use of this sometimes automated lubricator include: construction, for the lubrication of portable power tools such as chainsaws; industrial manufacturing, for the lubrication of material handling equipment such as chain conveyors; agriculture, for the lubrication of chains in farming machinery and equipment; and residential, for the lubrication of appliances and outdoor equipment such as power gardening equipment.

Proper lubrication is vital to the operation of equipment, and chain oilers can help to both optimize the performance of chain-operated machinery and enhance longevity. In addition, chain oilers are typically encased in a metallic body, an oil dispenser, to decrease contamination of the lubricant.

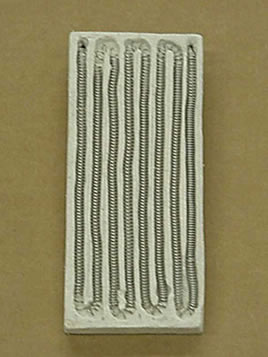

Chain oilers consist of a lubricant reservoir, a valve, a valve body and, at times, a brush to ensure even distribution of the lubricant. The lubricant reservoir is mounted atop the valve body and is often constructed from a combination of glass and metal such as aluminum or steel; however, the reservoirs can also be made of plastic.

The lubricant reservoir functions to store lubricants that are about to be dispersed to the area of the requiring lubrication. In chain oilers, the most common lubricants are synthetic oils, although mineral oils may also be used. There are a couple different types of valves that may be utilized in chain oilers, although needle valves are common for gravity-fed chain oilers, while solenoid valves are common for automatic chain oilers.

Needle valves are small valves with a slender point that enables precise regulation of lubricant flow, while solenoid valves are electromechanical valves that convert electrical energy into mechanical energy in order to distribute the lubricants. The valve body is typically small slender cylindrical tubes that contain the valve and protect both the valve and the lubricants being distributed from any harm.

Valve bodies are often constructed from metals such as aluminum alloys and steel, and can have brushes attached at the bottom to aid in lubricant distribution.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches