Oil dispensing is a way to store bulk oil in one place. Oil dispensers also help reduce, prevent or eliminate contamination during storage. Lubricants and oils can get contaminated while being delivered and stored. Further contamination can occur with incorrect dispensing and handling. Read More…

Graco's lubrication equipment division manufactures products used to dispense, meter and transfer motor and gear oils, grease, hydraulic and transmission fluids, antifreeze and other specialty lubricants. Our team of designers and engineers are committed to providing quality technical service and support on all our products. Call us or visit our website today!

At LSP Industries, Inc., we specialize in delivering comprehensive lubrication system solutions tailored to meet the demanding needs of modern industries. We pride ourselves on our ability to design, manufacture, and support innovative lubrication systems that optimize machinery performance and ensure operational efficiency. Our team combines decades of expertise with state-of-the-art technology...

The expert team at American Design & Manufacturing has over 100 years of combined knowledge in the design of customized lubrication systems, hydraulic equipment, heat transfer systems, gearbox assembly, cleaning equipment, specialty fabrication and test equipment. We utilize state of the art equipment and CAD design systems to create the best lubrication and other equipment for your application.

At Oil-Rite Corporation, we specialize in designing and manufacturing high-quality lubrication systems that enhance the efficiency and longevity of industrial machinery. Our expertise lies in providing innovative solutions that ensure precise and reliable lubrication, reducing wear, minimizing maintenance costs, and optimizing performance across a wide range of industries.

At Impact Fluids, we specialize in the development and delivery of high-performance lubricating systems designed to meet the rigorous demands of modern industrial operations. We take pride in offering advanced lubrication solutions that enhance equipment reliability, extend service life, and minimize downtime across a wide range of applications.

More Oil Dispenser Manufacturers

Bulk Storage Oil Dispensing Systems

Bulk oil dispensing systems are engineered solutions designed for the efficient storage and controlled distribution of industrial lubricants, hydraulic oils, and other essential fluids within manufacturing, automotive, and maintenance facilities. These advanced oil management systems offer a streamlined approach to handling large volumes of lubricants, minimizing waste, and ensuring workplace safety. Bulk oil dispensers typically consist of four to eight robust storage tanks, each with a capacity ranging from 30 to 240 gallons. Custom configurations are available to meet specific operational requirements, enabling facilities to optimize their lubricant storage and dispensing processes for maximum productivity.

Are you searching for a reliable bulk oil storage and dispensing solution to upgrade your facility’s lubrication management? Discover how modern bulk oil dispensing systems can reduce costs, improve workflow efficiency, and enhance compliance with industry safety standards.

Features of Oil Dispensing Systems

When evaluating oil dispensing systems for bulk storage, a variety of critical features and technical specifications should be considered to ensure optimal performance and regulatory compliance. Below are the key factors and options that define an effective oil dispensing solution:

- Cross-contamination prevention: To reduce the risk of lubricant cross-contamination, select systems with color-coded tanks, hoses, and taps. This is especially important in facilities where multiple types or grades of oil are stored and dispensed.

- Pressurized dispensing: Pressurized taps and high-quality hose reels help maintain the correct oil flow rate, ensuring rapid and spill-free dispensing.

- EPA and SPCC compliance: For facilities subject to environmental regulations, integrated spill containment trays and reservoirs are essential. These components help achieve compliance with EPA and SPCC guidelines for lubricant storage and handling.

- Fire safety: Quick-connect fire suppression hoses, auto-shutoff valves, and tank isolation valves provide critical fire safety and emergency response capabilities.

- Durable construction: Choose tanks constructed from high-density polyethylene (HDPE) or stainless steel for long-term durability, chemical compatibility, and resistance to corrosion.

- Pumping and filtration: Systems should include reliable gear pumps (preferably positive displacement gear pumps with internal bypass) and industry-standard beta filters to support filling, kidney-loop filtration, and clean dispensing of oils.

- Breather systems: Desiccant breathers are recommended for each tank to minimize moisture and particulate contamination, preserving lubricant quality during bulk oil storage.

- Modularity and scalability: Leading bulk oil dispensing systems offer modular tank arrays that can be expanded as lubricant requirements evolve—supporting the addition of more tanks or alternative oil types as your operation grows.

Still unsure which oil dispensing system features align with your facility’s requirements? Ask yourself: Which lubricants do you use most frequently? How many gallons do you need to store? Do you require compliance with specific safety or environmental regulations? Our expert team can help you select a system tailored to your application—contact us for a free consultation.

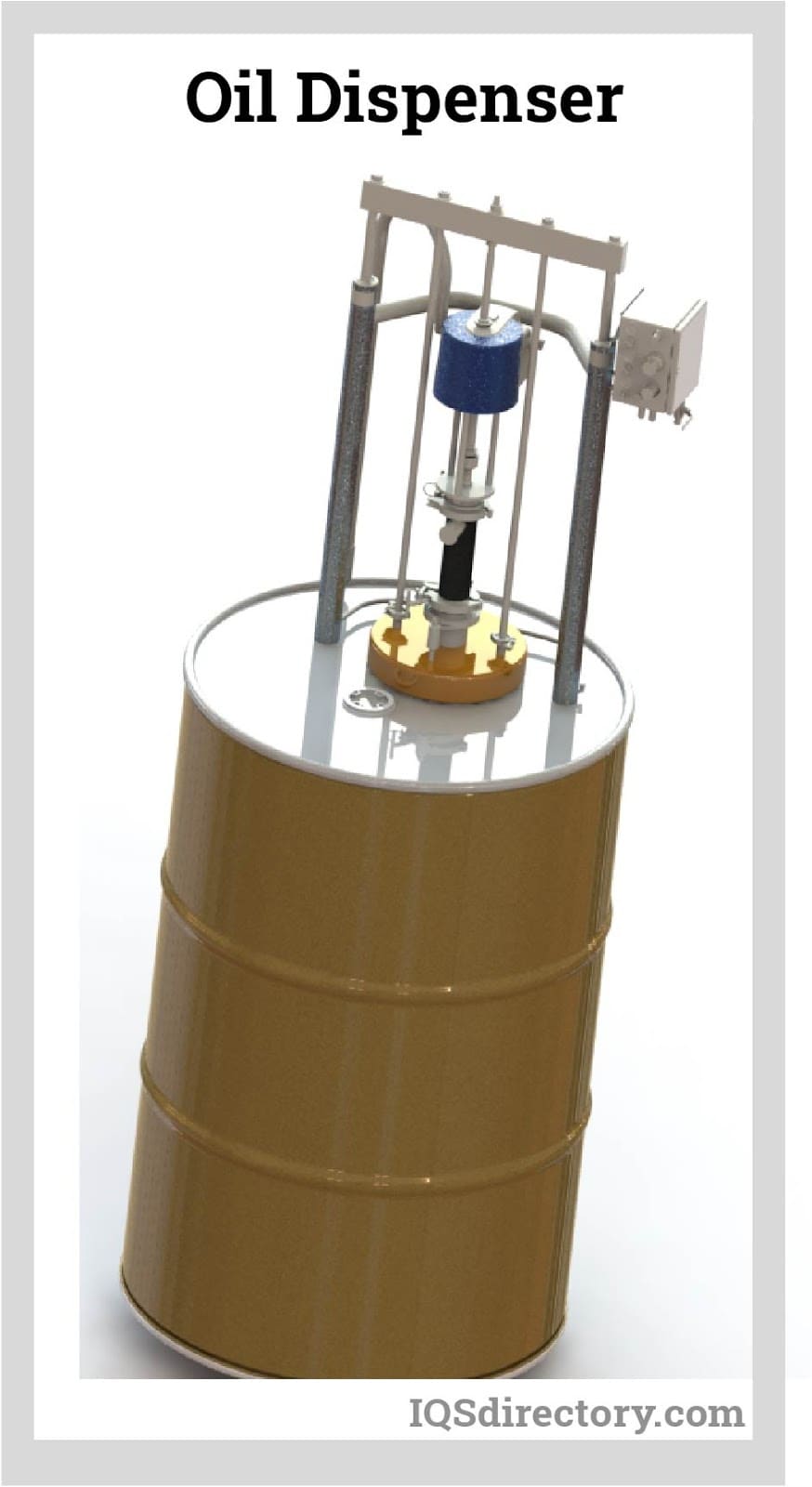

Oil Drum Dispenser Solutions

Oil drum dispenser systems are designed for businesses that require versatile, contamination-controlled, and space-efficient oil handling. These solutions are ideal for automotive workshops, service centers, manufacturing plants, and any environment where oils are stored in drums or totes. By integrating advanced contamination control features and modular storage options, oil drum dispenser systems streamline fluid management and reduce operational risks.

A typical drum or tote dispensing rack is engineered to accommodate large-capacity polyethylene totes, with a structure that positions the pump, hose reel, and filters beneath the tote and just above the spill containment tray. This design not only promotes safe oil handling but also makes it easier to maintain SPCC compliance by allowing for expandable spill containment tray capacity. Many features of the tote dispensing rack mirror those of traditional oil drum dispensing systems, including compatibility with forklifts for easy repositioning and integration with various pump motors and viscosity ratings.

To support efficient workflows, these systems include retractable hose reels fitted with trigger dispensers for precise and convenient oil transfer. The robust construction of drum and tote dispensing racks ensures reliable performance, even in high-volume or high-frequency lubrication environments.

Choosing Between Bulk Oil Dispensers and Drum Dispensing Systems

Selecting the right oil dispensing solution depends on several factors, including the volume of oil handled, the number of lubricant types used, available storage space, and specific workflow requirements. Bulk oil dispensers are best suited for facilities with high-volume needs, centralized lubricant management, and a focus on minimizing downtime. Drum dispensing systems, on the other hand, offer flexibility, modularity, and mobility—making them ideal for smaller operations, remote sites, or locations where oil types or volumes change frequently.

- Bulk Oil Dispensers: Best for high-volume, centralized lubricant storage and distribution. Supports transfer of multiple oil types, easy inventory management, and streamlined record-keeping.

- Oil Drum Dispensers: Ideal for smaller batch dispensing, frequent product changeovers, and mobile or decentralized workstations. Offers flexibility and easy expansion as your operation grows.

Applications of Oil Dispensing Systems

Oil dispensing systems are widely used across industries for managing engine oils, hydraulic fluids, gear lubricants, transmission oils, and specialty synthetic lubricants. Common applications include:

- Automotive service centers: Efficient oil change bays, fast lube shops, and vehicle maintenance facilities benefit from bulk oil dispensing for rapid, accurate service and inventory control.

- Manufacturing and industrial plants: Centralized lubrication of machinery, equipment, and production lines, minimizing downtime and ensuring process reliability.

- Heavy equipment and fleet maintenance: Construction companies, mining operations, and trucking fleets use oil dispensing systems for preventive maintenance and on-site refueling.

- Aviation and marine industries: Safe storage and dispensing of aviation oils and marine lubricants, with added focus on spill prevention and environmental compliance.

- Food processing and pharmaceuticals: Specialized stainless steel dispensing systems for sanitary lubricant management, meeting stringent regulatory standards.

Are you looking for oil dispensing system solutions tailored to your industry? Contact our experts for sector-specific recommendations and case studies.

Benefits of Advanced Oil Dispensers

Modern oil dispensing systems deliver a wide range of operational, safety, and financial benefits. Here’s how upgrading your oil management process can add value to your business:

- Economical operations: Bulk oil dispensers and stackable tote dispensing racks reduce overall lubricant costs by enabling bulk purchasing, minimizing packaging waste, and lowering transportation expenses.

- Safety and compliance: Integrated spill containment, fire suppression features, and EPA/SPCC compliance options help mitigate safety risks and legal liabilities in oil storage and dispensing.

- Inventory efficiency: Consolidate your entire oil inventory in a central, organized location. Modular systems can be easily rearranged or expanded as your lubrication requirements change.

- Clean, contamination-free dispensing: Closed-loop systems with advanced filtration and desiccant breathers prevent contamination, preserve lubricant integrity, and extend equipment life.

- Time savings: Automated and ergonomic dispensing equipment significantly reduces manual handling, spillage, and downtime, accelerating maintenance cycles and improving productivity.

- Space optimization: Stackable oil tote racks and compact tank arrays save valuable floor space and simplify oil handling logistics.

Key Decision Factors When Selecting an Oil Dispensing System

Choosing the right oil dispensing system requires careful consideration of your operational needs, available space, lubricant types, and compliance requirements. Here are the most important decision factors to evaluate:

- Capacity and scalability: How much oil do you need to store, and do you anticipate growth? Modular systems support easy expansion as your needs evolve.

- Fluid compatibility: Ensure the system materials are compatible with all oils and lubricants you intend to store (e.g., mineral oils, synthetics, biodegradable lubricants).

- Type of dispensing: Do you require batch, continuous, or metered dispensing? Consider systems with digital meters for precise inventory tracking.

- Environmental and safety regulations: Does your facility need to comply with EPA, SPCC, OSHA, or local fire codes? Look for integrated spill containment and fire suppression features.

- Ease of use and maintenance: Select systems with intuitive controls, easy-to-service filters and pumps, and minimal training requirements for staff.

- Customization and automation: Advanced systems may include programmable logic controllers (PLCs), remote monitoring, and automated dispensing for large-scale or multi-site operations.

How to Choose the Right Oil Dispensing System Supplier

Finding a reputable oil dispensing system company is crucial for long-term success and operational safety. To ensure the best outcome when purchasing an oil dispensing system, it’s recommended to evaluate multiple suppliers and compare their offerings, technical expertise, and customer support. Our Oil Dispensing System Directory allows you to compare at least four top-rated companies, each with a detailed business profile outlining their experience, technical capabilities, and service areas.

Each oil dispensing system company profile includes a direct contact form, making it easy to request product details, technical specifications, or a customized quote. Use our proprietary website previewer to explore each supplier’s specialization, manufacturing quality, and customer feedback. Our simple RFQ (Request for Quote) form allows you to reach multiple suppliers with the same request, streamlining your purchasing process and helping you secure the best price and service.

Frequently Asked Questions About Oil Dispensing Systems

- What is the difference between a bulk oil dispensing system and a drum dispenser? Bulk oil systems handle large volumes and multiple oil types in a centralized manner, while drum dispensers offer flexibility and mobility for smaller or changing needs.

- Are oil dispensing systems customizable to my facility’s requirements? Yes, most systems are modular and can be tailored for capacity, fluid type, automation, and compliance features.

- What are the maintenance requirements for oil dispensing equipment? Routine maintenance includes checking filters, inspecting hoses, calibrating meters, and verifying spill containment functionality. Many suppliers offer preventive maintenance packages.

- How do I ensure compliance with EPA and SPCC regulations? Choose systems with integrated spill containment, leak detection, and fire suppression features. Consult with your supplier about your specific regulatory needs.

- Can I integrate oil dispensing systems with digital inventory management? Yes, many advanced systems offer digital meters, PLCs, and remote monitoring integration for real-time tracking and reporting.

Have more questions? Contact us for expert answers and a free oil dispensing system consultation.

Get Started: Request Your Oil Dispensing System Quote Today

Whether you’re looking to upgrade existing oil storage, implement a centralized lubrication management system, or streamline compliance with environmental and safety standards, our team can help you design and source the perfect oil dispensing solution. Explore our Oil Dispensing System Directory or contact us directly for a no-obligation quote and product recommendations tailored to your facility’s needs.

Take the next step toward safer, more efficient oil management—request your personalized oil dispensing system quote now!

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches