Oilers use several different lubricating materials and can apply these materials by various means. Read More…

Graco's lubrication equipment division manufactures products used to dispense, meter and transfer motor and gear oils, grease, hydraulic and transmission fluids, antifreeze and other specialty lubricants. Our team of designers and engineers are committed to providing quality technical service and support on all our products. Call us or visit our website today!

At LSP Industries, Inc., we specialize in delivering comprehensive lubrication system solutions tailored to meet the demanding needs of modern industries. We pride ourselves on our ability to design, manufacture, and support innovative lubrication systems that optimize machinery performance and ensure operational efficiency. Our team combines decades of expertise with state-of-the-art technology...

The expert team at American Design & Manufacturing has over 100 years of combined knowledge in the design of customized lubrication systems, hydraulic equipment, heat transfer systems, gearbox assembly, cleaning equipment, specialty fabrication and test equipment. We utilize state of the art equipment and CAD design systems to create the best lubrication and other equipment for your application.

At Oil-Rite Corporation, we specialize in designing and manufacturing high-quality lubrication systems that enhance the efficiency and longevity of industrial machinery. Our expertise lies in providing innovative solutions that ensure precise and reliable lubrication, reducing wear, minimizing maintenance costs, and optimizing performance across a wide range of industries.

At Impact Fluids, we specialize in the development and delivery of high-performance lubricating systems designed to meet the rigorous demands of modern industrial operations. We take pride in offering advanced lubrication solutions that enhance equipment reliability, extend service life, and minimize downtime across a wide range of applications.

More Oiler Manufacturers

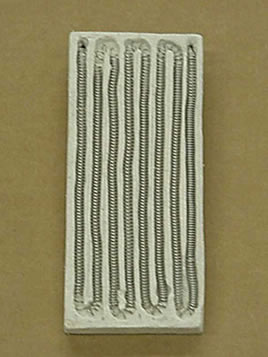

Oilers are lubrication equipment that applies petrol-based lubrication to machines and parts. Lubricant distribution can be powered by many means; it can be driven by manual labor or by pneumatic, hydraulic or electric power. Delivery techniques for lubricators include constant level, full flow, metered quantity, microfog and spray methods.

Constant level oilers involve automatic lubricators that provide a continuous supply of lubricant to machines and systems. The specific mechanics of constant level oilers are in short, a three part dispenser shaped like a trapezoid light bulb. A reservoir contains the additional oil at the top, while a pump is what pumps it out through the pumping house when the sensors let the automatic system know it is necessary.

Like other automatic systems such as the central lubrication system, which are full flow oilers, constant level oilers are often attached to the machine itself. Microfog lubrication delivers a mixture of atomized, micron oil particles and air. Spray methods would be done manually for occasional spot lubrication on machines without automatic systems attached.

Oilers are vital to manufacturing industries. Moving or rotating parts of machinery, such as dies, chains, spindles, pumps, cables, rails, bearings, and gears, need to be lubricated in order to continue to run smoothly and reliably. Oil is the perfect substance for this because it does not adhere and harden to surfaces, but keeps them smooth while protecting them from wearing out and corroding. The types of oil used for lubrication are usually mineral oils such as petroleum or synthetic oils.

Organic oils degrade to fast to be used as lubes. Large machinery with parts that need to be kept lubricated are employed by numerous industries, such as food and beverage, printing, packaging, industrial manufacturing, construction, aerospace, automotive, marine, power generation, oil companies and many others.

If a machine is involved in their production, then an oiler or other lubrication system is necessary. It is also a smart investment for a company, because it will keep maintenance costs down as well as keeping machines working longer and at higher qualities of performance.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches