Proper lubrication is important because without it there are many ill-effects such as higher than normal wear and tear, decreased machine accuracy and decreased production efficiency. As a result, lubricants are essential to maintaining efficiency and decreasing costs. Read More…

Graco's lubrication equipment division manufactures products used to dispense, meter and transfer motor and gear oils, grease, hydraulic and transmission fluids, antifreeze and other specialty lubricants. Our team of designers and engineers are committed to providing quality technical service and support on all our products. Call us or visit our website today!

At LSP Industries, Inc., we specialize in delivering comprehensive lubrication system solutions tailored to meet the demanding needs of modern industries. We pride ourselves on our ability to design, manufacture, and support innovative lubrication systems that optimize machinery performance and ensure operational efficiency. Our team combines decades of expertise with state-of-the-art technology...

The expert team at American Design & Manufacturing has over 100 years of combined knowledge in the design of customized lubrication systems, hydraulic equipment, heat transfer systems, gearbox assembly, cleaning equipment, specialty fabrication and test equipment. We utilize state of the art equipment and CAD design systems to create the best lubrication and other equipment for your application.

At Oil-Rite Corporation, we specialize in designing and manufacturing high-quality lubrication systems that enhance the efficiency and longevity of industrial machinery. Our expertise lies in providing innovative solutions that ensure precise and reliable lubrication, reducing wear, minimizing maintenance costs, and optimizing performance across a wide range of industries.

At Impact Fluids, we specialize in the development and delivery of high-performance lubricating systems designed to meet the rigorous demands of modern industrial operations. We take pride in offering advanced lubrication solutions that enhance equipment reliability, extend service life, and minimize downtime across a wide range of applications.

More Grease Dispenser Manufacturers

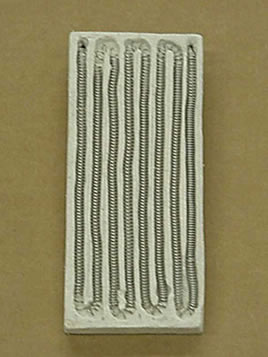

Grease, one of the more common lubricants, works exceptionally well for machinery that does not need to be lubricated too frequently. Because grease is such thick and viscous oil it will stay in positions that liquid oil from an oil dispenser would not. Formed from a mixture of oil and soap, various additives can be introduced into the mixture to develop desired characteristics. For instance, Teflon is a possible additive to grease that produces enhanced lubrication properties.

Commonly seen in the automotive industry, grease dispensers are essential in a wide range of industries including industrial manufacturing, for the lubrication of various process and assembly machinery; pharmaceutical, for use in research laboratories for the lubrication of glassware such as stopcocks and ground glass joints; food and beverage, for the lubrication of processing and packaging equipment; and construction, to lubricate various equipment and supplies such as hand-operated power tools.

Grease functions as a shear-thinning lubricant, meaning that its viscosity is reduced under shear, which is defined as stress that is applied in a parallel or tangential manner rather than normal stress, which is applied in a perpendicular method. When a sufficient level of shear is achieved, the viscosity of the grease drops and becomes similar to that of liquid oil, thus functioning as a lubricant.

Grease dispensers generally consist of three essential components: a pump, a gear set and some kind of control system or feature. Most grease dispensers have a motor, but since they can be powered in a couple of different manners including manual, electromechanical and pneumatic, they could also be powered through a hand-lever.

In terms of what kind of pump is used, grease dispensers often use a positive displacement pump, which functions by trapping a fixed amount of grease and then forcing it into the feed lines. The grease is taken from the reservoir, which is a container that stores the grease until it is needed to be dispersed or once the grease has left and returned again from area of lubrication.

Grease dispensers can feed one or more areas of lubrication. Grease dispensers that have a single point of lubrication are used on small machine applications, while grease dispensers with multiple points of lubrication are used for medium to large sized machines.

Conveyor Belting

Conveyor Belting Conveyor Systems

Conveyor Systems Conveyors

Conveyors Hosereels

Hosereels Industrial Lubricants

Industrial Lubricants Lubricators

Lubricators Screw Conveyors

Screw Conveyors Pneumatic Conveyors

Pneumatic Conveyors AGV

AGV Air Pollution Control

Air Pollution Control Assembly Machinery

Assembly Machinery Blowers

Blowers Cranes

Cranes Deburring Machinery

Deburring Machinery Dust Collectors

Dust Collectors Heaters

Heaters Hose Reels

Hose Reels Mezzanines

Mezzanines Modular Buildings

Modular Buildings Storage Racks

Storage Racks Ultrasonic Cleaners

Ultrasonic Cleaners Work Benches

Work Benches